Ans: Generally not, unless it has gone through testing for certification for potable water or has specific barrier layers.

What Is The Difference Between Blue and Black MDPE Pipe

The main difference between blue and black MDPE pipe are their intended uses, color-coding guidelines, and UV resistance.The decision among blue vs black MDPE pipe in most projects is influenced by sunlight exposure, installation location, and water quality.MDPE (Medium Density Polyethylene) water pipes are some of the most popular options to use within the water infrastructure field due to their flexibility, robustness, and corrosion-resistant nature. However, not all MDPE pipes are the same.

The two main variants you are likely to come across are blue and black pipes, but it’s important to understand the differences between these two types of MDPE, their purpose, material properties, sizing and applications to properly select, install, and be compliant with regulation.

Learn about Medium Density Polyethylene Pipe (MDPE) colors and their uses from goflo MDPE pipe solutions.

This article will explain in full detail, the way the pipes differ, and what you should consider when deciding on them.

Why Colours Matter: Colour Coding in MDPE

The MDPE pipe colour code shows whether a pipe is safe to use for drinking water from the mains or for general water distribution and irrigation.One of the simplest ways to distinguish pipe function at a glance is via colour coding. In many standards and industry practices, different colours of polyethylene pipes indicate different intended uses:

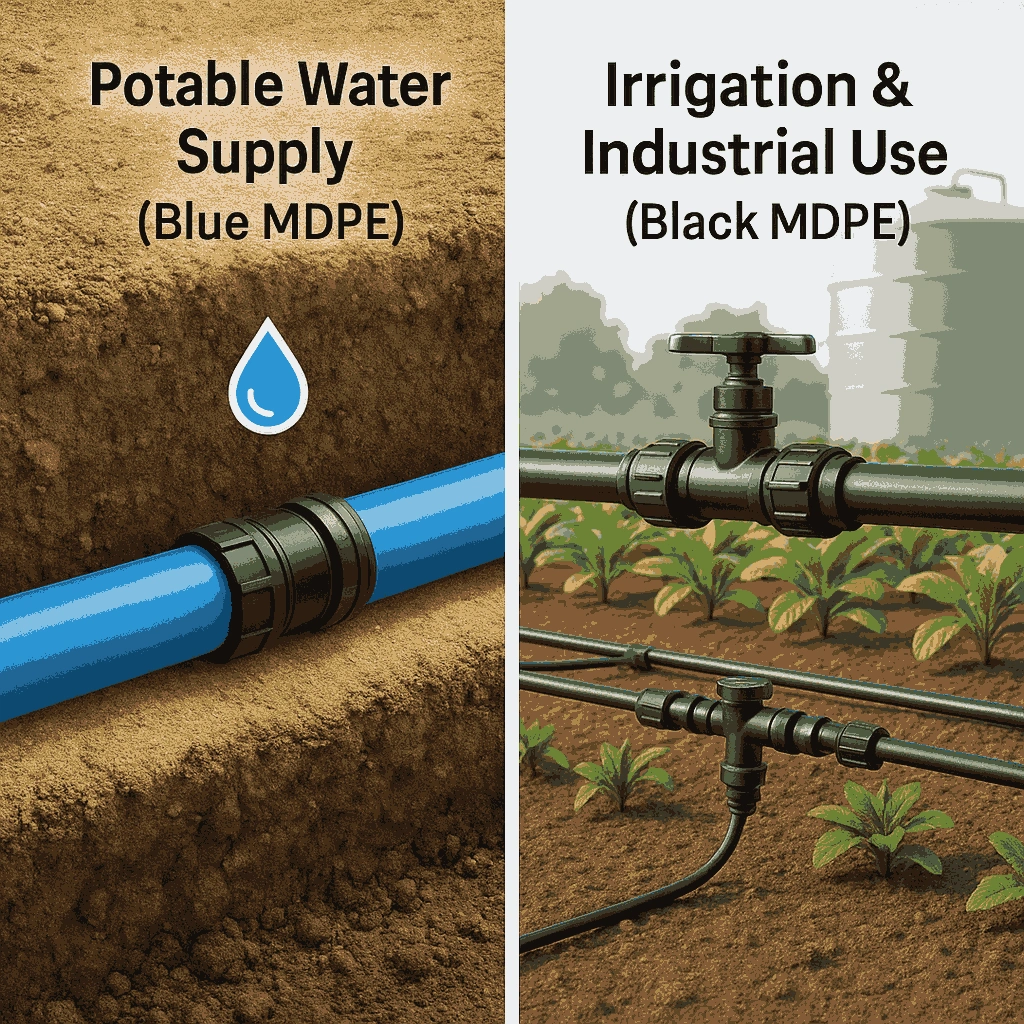

- Blue MDPE is commonly used for potable (drinking) water supply lines, especially when buried underground.

- Black MDPE is often used in non-potable water, industrial, irrigation, or pressurized above-ground applications.

- Other colours (e.g. yellow) are reserved for applications like gas piping.

Colour coding helps plumbers, engineers, and maintenance crews to quickly identify pipe roles in a network, avoid errors during installation, and maintain safe separation of different fluid systems.

For Water Management Solutions to prevent errors and guarantee safety, proper color coding is crucial.

Material and Construction Differences

The biggest differences between blue vs black MDPE pipe are the grade of the material, how well it resists UV rays, and how long it lasts.

Base Material and UV Stabilisation

Black pipes include additives for MDPE pipe UV stabilisation, making them suitable for sunlight exposure, because of this UV protection, common black MDPE pipe uses include above-ground installations and irrigation systems.

Blue MDPE is generally created for below ground use with potable water, and as such, it will not be made with very much UV stabilisation. In fact, the pipe may be degraded by sunlight and warmth if it is/intentionally left above ground long term.

Black MDPE probably contains a carbon black additive which gives it UV resistance; thus, black is best used with above-ground or exposed service. The UV stabiliser in the carbon black helps protect from sunlight degradation.

Pressure Rating, Wall Thickness & Dimensions

The pipeline can manage water flow and long-term operating pressure without failing if the appropriate MDPE pipe pressure rating is chosen.While many blue and black MDPE/HDPE have similar outer diameter sizes in nominal size (20 mm, 25 mm, 32 mm, etc., up to 63 mm in smaller systems), differences in wall thickness or tolerances might even occur in practice.

In other words, if you assume fittings, couplings, or adaptors from different suppliers are all the “same” nominal size, with blue pipe or black pipe, they may not always fit right. Additionally, black or industrial types have been rated for higher pressure service or more aggressive service conditions, which may result in a larger wall thickness (or an SDR).

It’s a good practice to check the manufacturer’s published pressure rating (PN) and standard dimensional ratio (SDR), since nominal color should not warrant your association.

See the comprehensive article on Difference Between MDPE Pipes and HDPE Pipes to learn about the technical distinctions in terms of wall thickness and pressure rating.

Application & Use Cases

Blue MDPE – Ideal for Potable Water Underground

Safe drinking water supply lines and subterranean mains connections are the two most popular applications for blue MDPE pipe uses.Blue pipe satisfies hygienic requirements for both residential and commercial use and is authorized as MDPE pipe for potable water.

Blue MDPE pipe is the preferred option for underground water mains, branches and service connections to drinking water. The blue coloration easily identifies a drinking water line to utility workers and contractors to avoid cross-connection with irrigation water, sewage, or industrial water systems.

Copper plumbing will corrode, but MDPE will not rust, rot or react with chemicals in the soil. The smooth inner surface also inhibits buildup of scale, and promotes efficient water flow. Blue-coded MDPE is widely accepted and approved by regulatory authorities as the standard trusted method of safely conveying drinking water.

Using MDPE Pipes Safe Drinking Water for underground potable water supplies guarantees compliance to quality and safety regulations.

Black MDPE – For Industrial, Irrigation, or Above-Ground Installations

External systems exposed to sunlight, agriculture, and industrial water movement are common uses for black MDPE pipe.For farms and gardens, black pipe is preferred as the ideal MDPE pipe for irrigation.

Black MDPE pipe is typically used in applications where the water is not intended for drinking, or when pipes are used outdoors. These pipes work great for irrigation systems for agricultural fields, parks, and gardens; industrial water supply lines; temporary systems; and distribution of sewage or other non-potable water.

In above-ground installations, black MDPE pipe has better performance due to its UV stabilization, though prolonged exposure to sunlight will still require UV protection. Some black pipes manufactured with higher strength PE or HDPE can handle increased mechanical stress

But in general, black MDPE pipe is not approved for drinking water without certification or protective barrier layers.

Sizing and Fitting Challenges

Common MDPE pipe fittings are typically compatible with both black and blue pipes, making installation easy.However, when combining older fittings with more recent pipe standards, installers may encounter MDPE pipe sizing problems.

Even with both blue and black pipe having the same nominal size, differences in tolerances, wall thickness, or manufacturing can make it difficult to use fittings that are interchangeable.

For example, a 25mm black pipe will likely have a slightly different (up, even down) outside diameter than a 25mm blue pipe from another manufacturer. This may affect compression fittings, couplings or adaptors to fit parts of the system together correctly.

Older systems (e.g. older ‘alkathene’ or legacy black pipe) may differ even more in their dimensional tolerances resulting in the need for specific adaptors or transition couplings to join to modern blue MDPE.

Fittings should always be matched by the actual outside diameter, SDR/PN rating and ‘fit’ or compatibility not just by assumed identification, same nominal = same fit

Some suppliers have a conversion chart or compatibility chart which they provided to assist installers for different brands or colours.

Strengths, Limitations & Lifespan

The MDPE pipe lifespan and durability depends on installation, pressure class, soil conditions, and UV exposure.

Durability and Lifespan

Both blue and black MDPE pipes are designed to provide many years of service. The service life of buried water applications is typically estimated at 50 years or longer. Under the best conditions, some might even extend a century or more. Being an inert material, MDPE pipe has resistance to corrosion, microbial growth, and many soil chemicals.

Service life is based on appropriate burial depth, appropriate backfill, absence of mechanical damage, and consideration of UV stress from high-intensity sunlight (blue pipe only). Also, black pipe can tolerate UV better if not covered, but requires adequate support, protection from abrasion, and consideration of thermal expansion.

goflo provides MDPE and High Density Polyethylene Pipe options for durable pipelines.

Weaknesses & Considerations

Here are some of the weaknesses and considerations that you need to keep in mind. This includes:

Blue pipes have a very short lifespan when exposed to sunlight, while black pipes have a longer lifespan, but protection is recommended if the pipe is used in an application that will last for a long time.

Polyethylene becomes weaker and weaker at elevated temperatures, so neither blue, or black MDPE is suitable for transporting medium, or hot water.

If pipes are to be exposed to loads, impact, or ground movement, adequate wall thickness and support design must be utilized.

A joint will fail regardless of whether the pipe is blue or black if the joint is installed under poor service conditions. Joints should comply with the pressure and tolerances of the pipe.

Selecting the best option for irrigation, industrial use, or potable water becomes easy and safe once you know the true differences between blue and black MDPE pipe.

FAQ’s

Q. Is it safe to use black MDPE for drinking water?

Q. Why is blue MDPE not suitable for above ground installation?

Ans: Blue MDPE pipes do not have UV stabilizers, and since they will be exposed to sunlight, there is the risk of degradation, brittleness, and premature failure over time.

Q. Can blue MDPE pipe fittings be used with black MDPE pipe fittings?

Ans: Not necessarily. While the nominal size can be the same, there are dimensional and tolerance variations that may not allow for the two to be used at the same time.

Q. What is the lifespan of MDPE pipes?

Ans: If they are installed correctly and properly protected, the pipes could last for a minimum of 50 years, although other factors like conditions of use and surrounding environments will also be factored in.

Q. Is blue MDPE pipe UV resistant?

Ans: Blue MDPE must be installed underground because it is not intended to be completely UV resistant.

Q. Which MDPE pipe is best for mains water?

Ans: Blue MDPE is the only recommended MDPE pipe for mains water because it meets drinking water quality standards.

Read more about practical applications of MDPE pipes in Water Treatment Plants from goflo.