What Are the Advantages of Using MDPE Pipes Over Copper, Steel, or PVC?

The selection of pipe material in any water supply or distribution project is far more critical than it may seem at first. Pipes are the backbone of a water (or gas) facility. They transport fluids considerable distances through different soil, pressure, and environmental conditions.

The material you choose affects not only installation performance, but also the durability, maintenance, safety, and cost for the future. Generally, the three most common materials used were copper, steel and PVC (Polyvinyl Chloride).

However, with advances in polymer engineering and the increasing demand for safe and long-lasting infrastructure, MDPE (Medium-Density Polyethylene) has emerged as a material that outperforms the older materials in several critical factors.

What Is MDPE (Medium Density Polyethylene)?

MDPE Pipes (Medium Density Polyethylene) is a form of polyethylene that possesses a density between the softness of LDPE and the rigidity of HDPE. This ascribed density yields the ideal combination of flexibility and strength, making it very well-suited for use in water and gas pipelines.

The material has become commonplace in potable water networks, underground gas lines, rural supply systems, and many industrial water distribution systems. In borewell applications in houses to municipality water grids, MDPE has the reliability and ease of use to be a staple in urban and rural installation projects.

Learn more about MDPE pipes in our full MDPE Pipes Guide

Comparing MDPE With Copper, Steel, and PVC Pipes

When engineers and contractors evaluate piping materials, they often consider a range of parameters, including service life, corrosion resistance, joint reliability, and cost. Copper has great thermal qualities, but it is expensive, and in some water types, copper is susceptible to a chemical reaction.

Steel is strong and durable, but it can rust, and it is a labor-intensive process to practice welding. PVC is low-cost, but has poor impact resistance and is brittle with age and in cold temperatures. MDPE offers a long service life, is chemically inert, very flexible, and has a much lower risk of leakage.

And all at a cost much below that of copper, and competitive to steel. A high-level comparison shows MDPE indeed leads in corrosion resistance, flexibility, impact resistance, ease of installation, and finally long-term safety, all achieving an expected service more than 50 years. Overall, MDPE would be a modern advancement over past traditional piping materials.

Key Advantages of MDPE Pipes Over Traditional Materials

1. Superior Corrosion & Chemical Resistance

MDPE pipe’s advantage is that it is resistant to rust and corrosion. Pipe systems made of steel will corrode in the presence of oxygen and moisture. MDPE is chemically inert even after decades of underground use. Copper can corrode due to acidic or contaminated water and leach metals or cause pinhole leaks.

PVC will become brittle when exposed to daylight and frequently fluctuating temperatures, although it may resist certain chemical reactions. MDPE avoids all of these problems. Its stability provides peace of mind related to water quality and the structural integrity of the pipe for decades.

2. High Flexibility for Easy Installation

The flexible MDPE Pipe greatly eases installation work. Since the pipe can bend with natural contours, it can be routed around rocks, uneven terrain, or existing utilities without multiple fittings.

This also cuts down labour time and reduces the number of potential leakage points. In underground installations, where soil is subject to constant movement from moisture conditions, the seasons, or small seismic movement, a flexible pipe performs much better.

Rigid materials such as steel and copper are prone to developing cracks or joint failure when subjected to movement, while MDPE absorbs the stresses easily.

3. Leak-Proof Joining Systems

Copper connections typically require soldering and steel connections require welding (both of which require specialised skills and expertise), whilst MDPE supports simple, highly rugged jointing methods.

Compression fittings provide a straightforward connection that does not require the use of complicated tools, and can be used by professional installers and in smaller DIY installations.

For larger water networks and gas pipelines, electrofusion (EF) joints are common practice. The EF process uses electrical heating to melt the pipe and fit it together as a singular monolithic connection. The resulting joint is often stronger than the pipe itself and produces a highly leak-proof joint, resulting in less water loss and maintenance costs.

4. Long Service Life (50+ Years)

MDPE pipelines are designed for durability. The material is designed to resist external mechanical stress and internal pressure spikes, as well as soil movement and chemicals.

In some locations, MDPE systems were installed multiple decades ago and are still in operation with little degradation. The durability of MDPE is valuable to municipal water networks and larger infrastructure projects that are designed for decades of use with little to no interference.

Where steel pipes may be required to be replaced within 20 to 30 years and PVC may become brittle after 20 years, MDPE facilities last longer than 50 years, making MDPE an ideal economic lifecycle.

5. Lightweight & Easy to Transport

MDPE is considerably lighter than metal pipes, making it considerably easier to move around on site and transport from site to site. This can result in reduced logistical costs and less physical strain on workers during installation.

Contractors can install MDPE pipe in long lengths with great ease, even in challenging or isolated environments where moving heavy materials or equipment would be extremely challenging or costly to do so.

Large-scale projects will also benefit from significantly shorter time taken and fewer machines and labour overhead needed to install, which will compound into cost efficiency.

6. Better Impact Resistance

Conditions at the time of installation are most often less than ideal. During trenching, backfill work, or handling, the pipes can be subject to sudden impacts or pressure from stones or machinery. PVC is particularly susceptible to cracking in such conditions, while metal pipes can dent or deform.

MDPE is far less prone to damage, and it can handle rough handling and uneven ground easily, thanks to its high impact resistance. This very toughness is the reason it has such high reliability and performance, especially in rocky soil or other construction-intensive sites.

7. Safe for Drinking Water

It is vital to maintain the quality of water and to keep it free of contaminants. MDPE is a food-grade, non-toxic material that does not change the taste, odour, or purity of drinking water. It does not leach metal or harmful products and is resistant to the deposition of bacteria in the water pipeline.

Copper and steel, under specific conditions, may leach metals into a water supply. Older PVC, also, will leach chemicals if exposed to heat or UV light over time. MDPE does not leach any chemicals into drinking water, which makes it one of the safest options available for drinking water systems.

Also Read: Are MDPE pipes safe for potable water?

8. Ideal for High-Pressure Water Supply

It is vital to maintain the quality of water and to keep it free of contaminants. MDPE is a food-grade, non-toxic material that does not change the taste, odour, or purity of drinking water. It does not leach metal or harmful products and is resistant to the deposition of bacteria in the water pipeline.

Copper and steel, under specific conditions, may leach metals into a water supply. Older PVC, also, will leach chemicals if exposed to heat or UV light over time. MDPE does not leach any chemicals into drinking water, which makes it one of the safest options available for drinking water systems.

| Feature | MDPE | Copper | Steel | PVC |

| Corrosion Resistance | Excellent | Moderate | Poor | Good |

| Flexibility | High | Low | Very Low | Low |

| Lifespan | 50+ years | 40 years | 20–30 years | 15–25 years |

| Joint Type | Compression/EF | Soldered | Welded | Solvent cement |

| Leak Risk | Very Low | Low | Medium | High |

| Cost | Low | High | Medium | Low |

| Drinking Water Safety | Excellent | Good | Moderate (rust) | Good |

MDPE vs. Copper – Detailed Comparison

Copper has always been appreciated for its robustness and antimicrobial properties, but it costs significantly more than MDPE, both in terms of material and labour to install. Copper experiences corrosion with certain aggressive waters, and pinhole leaks are a documented occurrence in older networks.

MDPE is completely inert by comparison. Additionally, copper theft is on the rise (especially in public or low-surveillance areas), increasing risk and damage costs. MDPE provides a corrosion-free, temporarily theft-proof, low-cost, and longer expected service life alternative.

MDPE vs. Steel – Detailed Comparison

Steel pipes are extremely strong but have serious downfalls for water systems. They are heavy, rust easily, and require welding or threading, which takes skilled labour and equipment.

Over time, the rust can taint the drinking water and reduce the internal diameter of the pipe, reducing flow efficiency. MDPE removes these concerns. It is light, does not corrode, and has a very simple jointing system, which makes it much cheaper to install and maintain.

Although steel sometimes looks cheaper upfront, MDPE becomes a less expensive investment over the course of the lifecycle because of its lower costs for installation and maintenance for most water distribution applications.

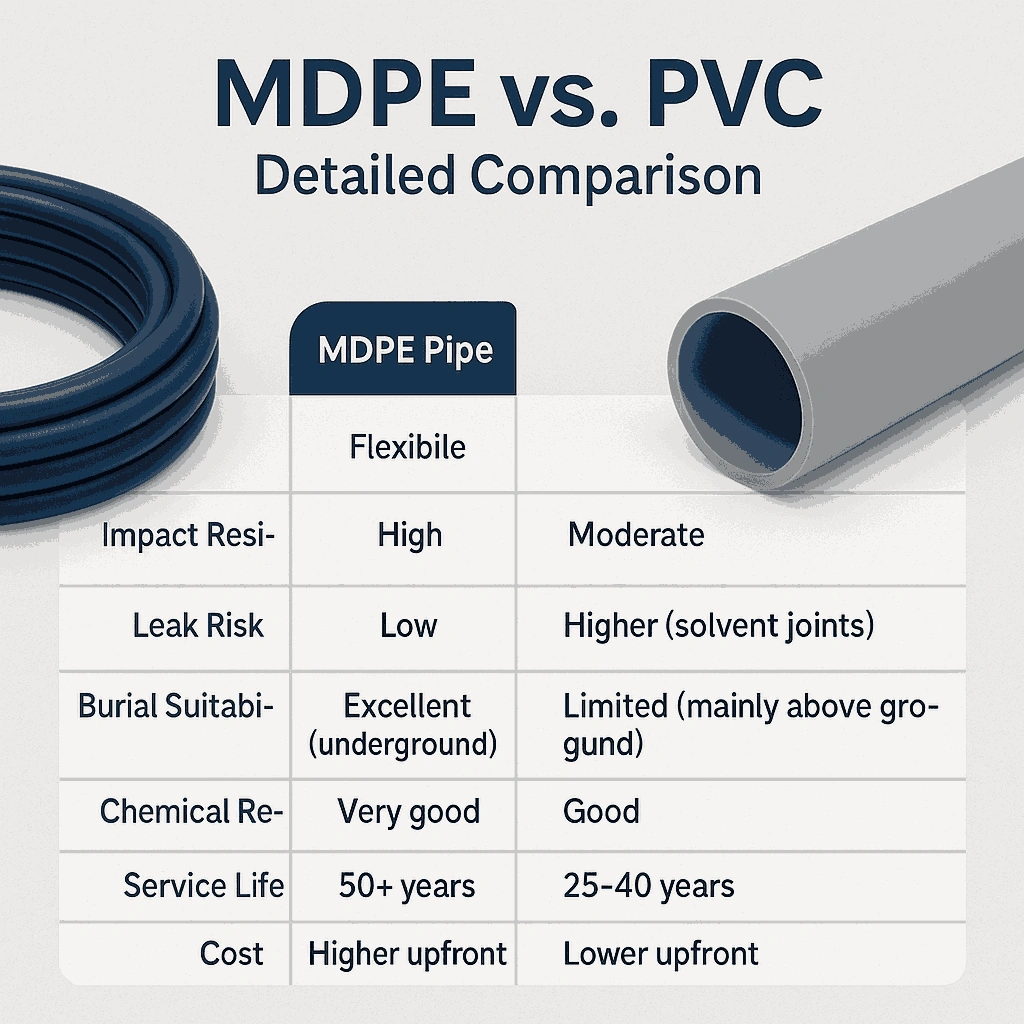

MDPE vs. PVC – Detailed Comparison

PVC is widely used in low-cost projects, yet its inflexibility and low impact strength make it ineffective in rocky soils and construction-heavy environments. PVC loses its impact strength when exposed to cold temperatures, increasing cracks and burst potential.

MDPE is significantly more flexible and tough against impact, and thus is better suited to accommodate many climate and terrain variations. In addition, MDPE can withstand fluctuations in pressure better than PVC. These factors make MDPE a better, more dependable option for long-term, large-line water distribution.

When Should You Choose MDPE Pipes?

MDPE is well-suited for an array of water supply applications. It is most often used in homes from the borewell or the water meter to the overhead tank. In large township development, it is well-suited for large, networked systems due to its ease of installation and durability.

For municipal utilities, MDPE is the best option for main and branch distribution lines, being leak-proof and lasting for many years. Also, in industrial applications, MDPE is the best option for high-pressure and chemically-neutral water with little to no maintenance, and to ensure flow. In all, when reliability, longevity, and safety are important, MDPE material performs well.

The goflo Advantage – High-Quality MDPE Pipes Installations

goflo specializes in professional MDPE pipe installation services that follow strict IS standards to ensure long-term durability and leak-proof performance. Our team ensures proper alignment, jointing, testing, and commissioning for potable water systems, using industry-approved practices and safety protocols.

We handle installations for residential, commercial, and large-scale municipal water networks with precision. Clients also receive on-site technical guidance, project supervision, and post-installation support to ensure system reliability and uninterrupted flow.

Final Thoughts – MDPE Is the Modern, Reliable Choice for Water Networks

As infrastructure needs change, conventional materials such as copper, steel, and PVC are slowly being replaced with newer, advanced materials. MDPE is a new product that is a realistic solution: it is flexible, stable in liquids and gases, has a long service life, and carries water safely and effectively.

MDPE’s performance in small- and large-scale networks makes it an intelligent investment for residential, industrial, and municipal projects. However, if you are looking for a sustainable, affordable, and low-maintenance piping solution, MDPE offers the most compelling advantages over conventional materials.