If a black MDPE pipe is marked with a blue stripe and carries the appropriate approval for potable applications, then it can be utilized. However, standard black pipes without any markings would generally be seen as non-potable products.

What Are the Different Colors of MDPE Pipe, and What Do They Signify?

Medium-Density Polyethylene (MDPE) pipes are commonly used in utilities and infrastructure due to their flexibility, durability, and corrosion resistance. One of the key advantages of MDPE pipes is their distinct color coding that aids in identifying what a pipe is used for, important for engineers and contractors and maintenance teams.

The color coding is essential for safety, recognition of the use of the pipe for proper design and installation, and appropriate process for regulatory standards. Even though MDPE pipes may appear materially and structurally the same, the specific color is indicative of the application or utility service being provided by the material.

Knowing the use of coded colors in MDPE pipe is critical to a proper installation for safe operations and effective utility infrastructure management, particularly in work environments where multiple utilities are in close proximity.

Quick Overview – Why MDPE Pipes Have Different Colors

Purpose of Color Coding in Utility Networks

Color coding of MDPE pipes is designed to provide for easy, clear identification of buried utilities. It allows installers, engineers, and excavation crews to determine what service this pipe carries, without digging any further or having to rely on the documentation. Color coding will help reduce risk of cross connections and help utility planners standardize networks.

See Water Management Solutions for actual instances of MDPE pipe applications in urban areas.

International vs Local Color Standards

Various regions observe distinct colors conventions, although some colors are still recognized internationally. Many countries use either ISO or EN standards, but some are established merely by a local authority such as the BIS in India or WIS / IGN in the UK. Although these local standards may have their own variations, the main idea of a color applying to a utility remains the same.

How Color Helps in Safety, Identification & Excavation Work

Colors enable employees to quickly assess the risk of buried utilities. High-risk services, such as gas, use the highest luminescence colors (e.g., yellow) to warn those excavating. Utilities for water and drainage use softer colors like blue and green to differentiate them from high-risk services. When repairing or maintaining a utility, colors provide technicians with a quick way to identify the correct pipe to isolate and finish their work efficiently and safely.

Safety is ensured by proper installation and fittings; for comprehensive instructions, see MDPE Pipes & Fittings.

Standard MDPE Pipe Colors & Their Meanings (Global + India + UK Standards)

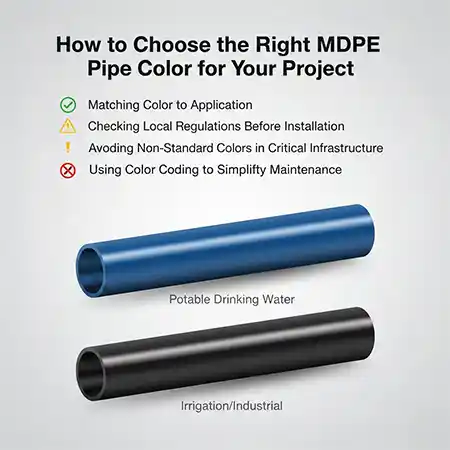

Blue MDPE Pipes – Potable Drinking Water Supply

Typically blue in color, MDPE pipes signify potable water supply lines used in underground cold water systems and meet strict health and safety standards applicable to potable water. MDPE pipes in various applications are used by municipal infrastructure, commercial, and residential connections to water service. By their common color coding, MDPE pipes distinguish potable water supply lines from recycled water or wastewater systems.

Black MDPE Pipes – Non-Potable Water / Irrigation

Black MDPE pipes are designated for applications other than drinking water such as agricultural irrigation, moving water for industrial purposes, and recycled water supply. In some areas, black pipes may have purple stripes that signify they are for recycled water use. Black MDPE pipe applications may not have the same sanitary requirements as potable water and, therefore, can be used for economical transportation of water service.

For irrigation, MDPE pipes are incredibly durable; see Advantages of MDPE Pipes Over Copper, Steel, and PVC for more information.

Yellow MDPE Pipes – Gas Distribution

Yellow MDPE pipes indicate underground gas lines and are considered the most standardized color in the world. These are also used for medium-pressure gas networks and engineered for safety with excavation activities. The bright yellow color gives workers a clear indication that the pipe carries a flammable utility and there should be caution and care when working near and around it.

Orange MDPE Pipes – Electrical & Communication Ducting

Orange MDPE pipes identify electrical and communication ducts to protect underground cables. They are also used for fiber-optic or telecom conduits, based on regional naming conventions. The color also enables cable technicians and operators to carefully distinguish them from other services like water or gas utilities.

Purple / Lilac MDPE Pipes – Reclaimed / Grey Water

Purple or lilac MDPE pipes are for reclaimed or grey water systems. They are used to convey water that has been recycled and used previously, such as for flushing toilets, irrigation, or industrial purposes. The color designation is to help prevent accidental cross-connection with drinking water lines and support water conservation in modern building systems.

Green MDPE Pipes – Sewer & Drainage Applications

Green MDPE pipes are alternatively used in sewer and drainage applications. They convey low pressure sewage, stormwater, and effluent. The color indicates the movement of wastewater and helps avoid confusion with potable water or gas lines during installation or repairs.

For projects involving water treatment and utility applications, check Water Treatment Plants.

Black with Blue Stripe – Potable Water (Alternative Variant)

These pipes are intended for situations in which a solid blue pipe is not required, or where the manufacturing standards have permitted black pipes with colored stripes. The blue stripe is located on the pegboard for easy recognition of drinking water service and the base black color gives off a robust reflection of strength and UV resistant.

Black with Yellow Stripe – Gas (Alternative Variant)

Black MDPE with a yellow stripe offers an economically favorable alternative to a solid yellow pipe in a domestic gas service connection. The yellow stripe denotes a prominent warning that the pipe contains gas, and service is to be carried out with caution.

Why Color Coding Matters in Utility Management

Preventing Accidental Damage During Excavation

Using colors to identify buried utilities can prevent inadvertent strikes by allowing immediate location of what is underground. Excavators can determine how to dig (methods, machinery, and safety considerations) based on pipe color.

Ensuring Correct Utility Connections

Using color on utilities also allows for technicians to connect the proper utilities without the risk of connecting gas to potable water, recycled water or drainage lines.

Reducing Repair Time in Emergency Situations

In case of utility failure, having buried utility lines color-coded enables maintenance crews to quickly identify the proper line, and, more quickly ultimately fix the service. The quicker the line is identified, the quicker return to service and less interruption to the community.

Compliance with Utility Regulations & Standards

Most regions have utility codes that specify color, for example, red for electric, blue for water etc. It aligns with the utility regulations for colors, while also promoting safety of the systems, long term consistency of the systems in the future.

Color Standards Followed by Manufacturers

BIS (India) Standards – IS 4984, IS 14885

Most manufacturers in India use our standard IS 4984 for water supply pipes and IS 14885 for gas piping. These standards help articulate colors, grades of materials, and performance requirements within guidelines for similar quality.

UK Water Industry Standards (WIS/IGN)

The WIS/IGN guidance from the UK provides clear specification of colors according to their respective end use, such as water, gas, or ducting. This becomes a baseline of standardization for utilities and contractors.

ISO & EN Color Guidelines

Generic guidance for identifications and pipe colors has also been established by standardization bodies, like ISO and EN. Countries typically implement or adapt the guidance provided by these international bodies.

However, the fundamental principles and generic guidance created guidance and identifications for utilities worldwide; countries, and individual utilities may apply the underlying elements based on different factors like climate, soil conditions, legacies, or previous systems identification.

MDPE Color Variations by Application Sector

Water Utility Sector

The water utility sector utilizes blue pipes for drinking water and black or green pipes for non-potable water services. As consumers we learned through the years to recognize pipe colors that helped us maintain some degree of separation between treated and untreated water networks.

Gas Distribution Networks

As for heritage color systems, Gas networks are the most defined across a variety of utilities. All gas pipes are yellow pipes. The visibility and recognition factor of yellow creates a certain safety factor for the public and our workforce.

Agriculture & Irrigation

The agricultural user typically selects to buy a black MDPE pipe because of its UV stability and its ability to use non-potable water. In many cases, the irrigation systems pipe is simply a black pipe with or without some stripe of color.

Telecom & Electrical Ducting

Orange pipe is the predominant color for underground telecommunication and electrical applications. The color is another guideline for the cable technician when they view the orange colored pipe, knowing it is not a water or gas pipe while excavating for installation or maintenance.

How to Choose the Right MDPE Pipe Color for Your Project

Matching Color to Application

The first step is to determine the service type: potable water, gas, communications ducts, sewage, or irrigation. Each of these service types has a designated color, and those colors improve safety and compliance.

Checking Local Regulations Before Installation

Local and regional standards may differ, and it is prudent to research and certainly confirm local color standards prior to installation. Identifying the appropriate color ensures compliance with regulatory, municipal, and organizational requirements.

Avoiding Non-Standard Colors in Critical Infrastructure

Non-standard colors could be detrimental for services vital for human welfare, like potable water or gas. Using recognizable colors is important, and changing established or recognized colors could cause continued confusion that would risk safety.

Using Color Coding to Simplify Maintenance

The correct color code eliminates confusion when repaing, replacing, and maintaining services, making those duties more easily accomplished. Technicians will be able to swiftly identify the correct pipe and get the service back online faster, resulting in less organizational costs for service time.

Common Mistakes in MDPE Pipe Color Selection

Using Wrong Pipe Color for Potable Water

Selecting potable water pipes not marked with blue color coding creates confusion, potential for violating a local code requirement, and increases the likelihood for accidental contamination.

Mixing Recycled Water Lines with Drinking Water Lines

Recycled water pipes, which may also be referred to as dual recycled water pipes, and grey watertreat were should clearly separate these pipe systems using purple colored lines. Color confusion could lead to dangerous cross connections that could create unwanted contamination.

Using Non-Gas Pipes for Gas Distribution

Gas distribution networks have specific colors for potable and for recycled water, usually yellow or yellow stripe. Again, inappropriate color coding could lead to safety issues violating gas supply regulations.

Not Following Municipality Guidelines

Municipalities may state’s or publish info re: utility colors, if you are not following these guidelines this may cause compliance issues with the municipality, increase expense for re-work, or delay of project approval.

FAQs

Can black MDPE be used for drinking water?

Why does gas always use yellow MDPE?

Yellow is a highly visible color for warning, and it is widely recognized. It serves to identify that there are flammable gas lines, and pre-warns and alerts workers to be careful when working or excavating near the yellow pipes.

Are color stripes enough for identification?

Yes, stripes are used when full color pipes are not required. Stripes should clearly identify the use or type of product so long as they conform to local requirements for stripe color.

Can MDPE colors vary between manufacturers?

There may be slight variations in the “shade” of the color, but in general, the different manufacturers will all comply with the same required color-coding based on national, local or industry standards.

Conclusion – The Importance of Choosing the Right MDPE Pipe Color

Choosing the right color for MDPE pipe is very important for safety, legal compliance, and future reliability of the utility network. The colors are to differentiate between the pipelines, minimize digging hazards and assure the pipeline can be correctly identified during its entire functional life. Checking local standards and codes before installing can mitigate risks that the project is not completed safely, legally, and anticipates future management.