Ans: The typical required pressure for MDPE hydrostatic test is usually 1.5 x Maximum Operating Pressure (MOP) of the pipe. For example, if a pipe was designed for 10 bar MOP, then the hydrostatic test pressure should be at the 15 bar range. This pressure is usually maintained for 30 – 60 minutes to make sure there is stability of the pipeline and there is no leakage in the MDPE pipe during the testing.

How to Test MDPE Pipes for Leakage and Durability (Complete Testing Guide)

Proper MDPE pipe testing is vital in terms of the pipe’s performance in terms of leaks and longevity. Conducting a proper MDPE leakage test and MDPE pipe durability test can save more expensive water loss and damage.

Testing ensures that the joints have been correctly fused, that the pipe is suitable for the application pressure rating, and that the workmanship standards for the installation may adhere to are all met. One important testing section is quality assurance tests that confirm that relevant regulatory standards, such as ISO, BIS, or ASTM provisions, are met, depending on the application and region.

In larger-scale projects, third-party testing and documentation on the various properties is often required as a commitment before commissioning a project. This leads to proper quality testing and assurance, and knowing that the network will be leak-free, maintenance costs to a minimized, and pipeline infrastructure will continue to perform over time with reliability for decades!

Pre-Testing Checklist for MDPE Pipes

Make sure that prior to commencing any tests, the site is prepared to carry out MDPE pipe installations testing. Conducting a swift water pipeline testing checklist would be an assurance that all pipes are clean, both ends attached, and that they are ready to be tested.

Prior to any hydraulic or pneumatic testing, the pipeline should also be subjected to an initial inspection phase. The first step is to confirm the pipe grade, commonly PE80 or PE100, which has specific limitations in terms of its pressure rating and mechanical properties.

The SDR (Standard Dimension Ratio), or the ratio of pressure stiffness, is essential, and therefore, the compliant SDR must equal the requirements outlined in the project. Fittings, compression joints, and electrofusion junctions should be inspected for defects in manufacturing and for any debris or contaminants.

The pipe barrel ends should be cut squarely or flush to the fitting using pipe cutters, avoiding saws entirely to prevent rough edges that will not seal. If foreign materials or debris are present at the joint, some will be dust or moisture; these should be removed before introducing any pressure testing, to avoid micro-leakage once testing has started.

1. Visual Inspection Test

The first process of MDPE pipe testing is a close visual inspection, and with the help of it, cracks, deformations, and loose fittings may be detected and they may influence the performance.

While MDPE pipes are durable, they can be damaged by ultraviolet light, mishandling, abrasion, and other external factors which can compromise their structural integrity and lead to early failure. A consistent visual inspection helps engineers identify defects early before installation, which minimizes the burden of rework after installation.

2. Hydrostatic Pressure Test for MDPE Pipes (Most Important)

The most efficient way to examine leaks is to have a hydrostatic pressure test for MDPE. The MDPE leakage test is verified by placing pressure that exceeds the normal operating pressure to ensure that the pipeline has met the test of durability.

Purpose

Hydrostatic Pressure testing is the most essential method to monitor the integrity of MDPE pipe.This MDPE pipe testing step is done to ensure that there is integrity of joints and material strength. The process involves filling the pipe until it is filled with water and then setting pressure and checking on the leakage. The test will pass when leakage under the stipulated pressure is zero.

Steps

Start by installing the pipeline all the way through, including any and all fittings, valves, and joints. Fill the line with clean water; and to eliminate any air locks, open the air release valves. Air traps provide false-pressure readings.

When the line is completely primed, apply a test pressure of 1.5 times the rated working pressure of the pipe. The pressure should hold between 30-60 minutes, depending upon the size of the pipe or regulatory agencies.

During the hold period, observe the pipeline for any visible leakage, damp spots or loss of pressure on the gauge. If the gauge holds steady, the install is performing correctly.

Pass Criteria

The pipeline has passed the hydrostatic test if there is:

- No visible leakage.

- The pressure drop is within allowable limits.

- No displacement or deformation of joints.

This test is required for commissioning, water supply projects and is the agreed gold standard of investigations.

3. Pneumatic Test – Air Pressure Leak Detection

In cases where there is no water, a pneumatic test of MDPE pipes can be applied. Even very minor leakage is detectable in an MDPE air pressure test yet safety measures are paramount as air is compressible and dangerous to handle.

When Used

Pneumatic testing is an option if water testing cannot be conducted, common in areas with limited or no access to water, high elevation, or temporary applications. Pneumatic testing replaces water with compressed air and tests the system for leaks.

Steps

The piping is sealed and pressure is applied steadily in a controlled manner using an air compressor. Maintaining pressure for a period of time indicates the line is third-party secure. If looking for micro-leaks, a soap-water solution may be sprinkled on joints, and formation of bubbles indicates potential leak points.

Safety Note

Caution must always be used, and the procedure must be conducted carefully. Compressed air holds substantially more energy than water at pressure, and if there is pressure failure this could result in pipe failure due to sudden burst. Pressure should be assessed gradually and personnel should remain clear of stress points during the testing phase.

Comparison Table: Hydrostatic Test vs Pneumatic Test

| Feature | Hydrostatic Pressure Test (Water) | Pneumatic Test (Air Pressure) |

| Medium Used | Water | Air |

| Safety Level | High (water is non-compressible) | Low (air is compressible → blast risk) |

| Leak Detection Accuracy | High for major leaks | Very high for tiny leaks |

| Recommended For | All MDPE pipelines | Small pipelines, temporary testing |

| Typical Pressure | 1.5 × Operating Pressure | 0.5–1 bar (low-pressure testing only) |

| Risk Level | Very Low | High |

| Ease of Use | Requires water filling/draining | Quick, no water needed |

| Industry Preference | Strongly preferred & standard | Used only when hydro test impossible |

| Cost | Moderate | Low |

4. Joint Integrity Test (Compression & Electrofusion MDPE Joints)

The checking of joints is important in the MDPE joint testing. Understanding proper MDPE installation practices ensures long-term reliability. The compression fitting leak tests and the electrofusion joint tests guarantee the safety of the connections used to avoid future leakages and the holding standards of the MDPE pipe durability tests.

For Compression Fittings

When installing systems with mechanical compression type joints, technicians must verify that they are tightened to the correct torque. Too tight can deform the surface of the pipe, too loose can allow for seepage under hydraulic pressure. After installation, the joints should be subjected to water pressure to check that they seal.

For Electrofusion Joints

In installation of systems using electrofusion (EF) joints, careful attention to detail is required. This may require verifying that the welding parameters are correct, properly scraping and aligning pipes prior to fusion and leaving the correct cooling time to eliminate the possibility of a cold weld occurring. An EF barcode reader may be utilized to document the welding parameters. In addition, a check for ovality and alignment will help ensure the long-term sealing ability of the joint.

5. Long-Term Durability Tests for MDPE Pipes

Long-term MDPE pipes durability tests are used to simulate the years of pressure cycles and environmental conditions to ensure that the pipe will stand the test of time over a period of decades without leakage or failure.

While long-term durability tests are usually performed at a manufacturing facility rather than at the job site, they remain important indicators of MDPE performance in real life under stress conditions.

- Slow Crack Growth (SCG): Resistance looks at how pipe withstands internal stress over the long term.

- UV Exposure Tests: Simulate a sunlight-degredation environment for above-ground installations.

- Tensile Strength Tests: Measure the elasticity (and elongation) possible before the fracture point.

- Environmental Stress Crack: Resistance (ESCR) determines the resistance to chemicals under harsh soil conditions.

Overall, these tests prove that MDPE pipes remain an excellent choice for long-term application in varying climates and chemical conditions.

6. Field Performance Tests for Contractors

MDPE pipes are subjected to field tests by the contractors to assure that the installed pipelines can withstand operational pressure. Periodic water pipeline testing prevents quality and leakage free operations.

Apart from lab assessments, piping contractors may also perform field tests to check that the performance expectations of the pipes under operating conditions are met. A flow test checks that the calculated discharge flows match the design and that pressure is distributed uniformly in the network.

A drop test, where pipes are dropped from measured distances, checks for damage from handling the pipes and assesses whether the pipes are structurally sound after impact.

The flexibility or bend test checks that the pipe behaves elastically and does not crack when bent around an object. All of these tests provide comfort during the installation and maintenance of pipes in harsh conditions.

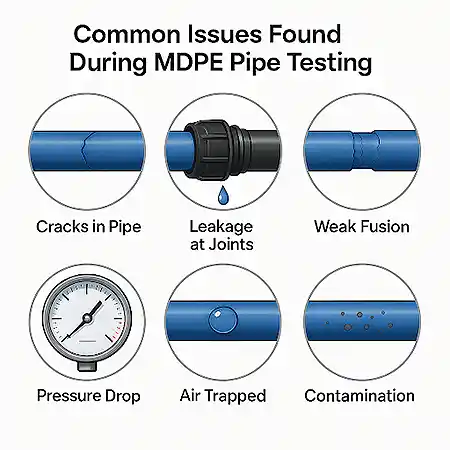

Common Issues Found During MDPE Pipe Testing

Minor leakages, misalignment of joints and pressure losses are the most prevalent issues in MDPE pipe testing. Determining such problems at an early stage of the MDPE leakage test will avoid future failures.

Testing often uncovers mistakes made during installation that can be avoided. Incorrectly tightening compression fittings continues to be one of the most common mistakes which lead to leaks. Also, if air is trapped in the pipeline, it can cause a decrease in pressure that can cause leaks and be mistaken for test pressure.

Improperly stored piping can cause damaged pipes due to stacking pipes over their length of time in sunlight or on an uneven base. In the same regard, choosing an SDR that is incorrect for the pipeline’s pressure may cause the pipe to deform or burst. Learn more about MDPE vs HDPE differences to make informed material choices. By practicing preventive procedures and selecting proper materials, more issues can be avoided.

How goflo Ensures Quality & Durability

goflo employs superior MDPE pipe testing systems and comprehensive MDPE pipe durability performance tests to ensure that all pipelines are leak-free and durable enough to offer confidence to the contractors and the end-users.

goflo guarantees unwavering performance, which is further assured by the consistent use of standardized raw materials, such as PE80 and PE100 grades that provide higher tensile strength and internal pressure resistance.

goflo also provides top quality compression fittings and electrofusion fittings that are designed to form reliable sealing surfaces, even when field conditions may vary.

To further assist contractors, goflo supports their installers by assisting with on-site testing of the product, to monitor the pressure tests on site, validate the joint and troubleshooting if anything is not functioning correctly.

We provide professional MDPE pipe installation and testing services across India, including Delhi, Punjab, Rajasthan, and Himachal Pradesh.

We assist contractors by ensuring that our product is 100% leak-proof quality, making sure that the project meets the current demand of infrastructure.

FAQ

Q. What is the recommended pressure for the MDPE hydrostatic test?

Q. How long should MDPE pressure testing last?

Ans: In a complete situation, MDPE pressure testing cycle generally needs 40print 90 minutes depending on pipe size and site position. The system is permitted to stabilise for 10-15 minutes and then followed by a pressure holding for 30-60 minutes. This duration helps to establish the fact that the MDPE pipeline can stand the pressure it is rated for without the pipeline exhibiting any signs of leakage or deformation.

Can MDPE pipes be tested with air?

Ans: Yes, MDPE pipe air testing (pneumatic testing) is possible, but not as preferred in comparison to water-based hydrostatic testing because air is compressible which increases safety risk. Pneumatic testing for MDPE is generally for small diameter pipes or where water is not available. Hydrostatic testing is, therefore, the safer and more reliable way to detect leaks in MDPE pipelines.

Q. What safety precautions are needed for pneumatic testing?

Ans: During the pneumatic testing of MDPE pipes, one should take strict safety precautions as air pressure can lead to sudden bursts. The pressure should always stay within recommended low levels, which are typically 0.5 – 1 bar, and workers must not be present by the pipeline during testing. Proper fitting, pressure relief valve, and avoiding high-pressure air testing are some of the ways to minimize the risks of MDPE air leak tests.

Q. What is the difference between hydrostatic and pneumatic testing for MDPE?

Ans: The major difference between hydrostatic testing and pneumatic testing of MDPE pipes is the medium used: hydrostatic tests use water, which makes it a safer and more preferable test in the industry, while pneumatic tests use air, which is more sensitive to small leaks but is more sensitive, due to the air compressibility factor. For large installations or long term reliability MDPE hydrostatic is the preferred test method while pneumatic is often switched too when dealing with smaller applications or lower pressures.

Q. What standards apply to MDPE pipe testing in India?

Ans: In India, the MDPE pipe testing is based on the international and national standards such as ISO 4427, 4437, BIS etc. defining the material quality, pressure ratings, and testing procedures for the safe performance of the pipelines. Adhering to these standards guarantees that MDPE pipes provide a guaranteed level of reliability in their durability, water operation without leaks and long-term strength in water distribution networks.

Q. How often should MDPE pipes be tested on site?

Ans: MDPE pipes are to be tested at key stages: once before installation for visual inspection and then once upon installation using pressure and a leak test to confirm the integrity of the system. For critical projects or long water distribution lines, contractors may also conduct annual MDPE field performance tests by which the pipeline is kept leak proof and structurally stable for the long haul.

Final Thoughts – Proper Testing Ensures Leak-Proof Water Networks

Good MDPE leakage tests and comprehensive MDPE pipe testing are important towards the development of good water networks. These testing procedures will guarantee the product is very durable in the long run and reduce the costs of maintenance.

MDPE pipes provide durability, flexibility, and the potential for longer-term cost savings, but they will perform well only with appropriate testing and installation practices. The first validation step in the testing of installation was visual examination of pipe and fittings. Hydrostatic pressure testing and other advanced durability testing methods followed to validate further.

Each test assures both safety and long-term viability of the system being installed.

Contractors, manufacturers, and project owners who implement structured testing protocols can eliminate much of the uncertainty associated with pipe and fittings performance with respect to the failure mode, as well as maximizing the longevity and safety of potable water distribution systems.