Ans: goflo only uses certified virgin-resin MDPE/HDPE pipes utilizing electrofusion joints, ensuring flexible, durable, zero-corrosion, and a long-term guarantee of leak-free service.

Water Infrastructure Challenges in Tier-2 Cities – and the goflo Solution

Water infrastructure challenges in tier-2 cities with goflo MDPE and HDPE solutions

Tier-2 cities throughout India are growing at a faster pace than their water systems can accommodate, resulting in the accumulation of pressure on municipal systems, developers, and residents. Aging infrastructure, non-revenue water loss, contamination, and old sewage systems contribute to unreliable and insufficient water supply.

Builders and contractors also face challenges with durable pipe sourcing, low pressure, and STP/WTP compliance. goflo eliminates these challenges with a full suite of MDPE/HDPE piping, electrofusion jointing, hydraulic modeling, and fully engineered STP/WTP systems. By delivering comprehensive design, installation, and maintenance services, goflo provides both leak-proof, durable, and efficient water systems.

For tier-2 cities focusing on sustainable urban development, goflo provides a reliable, cost-effective, and future-ready solution that reinforces the whole water ecosystem.

Why Tier-2 Cities Are Facing a Water Infrastructure Crisis

Cities in tier-2 parts of India are rapidly expanding: there are new residential townships, gated enclaves, and city developments happening all around. Urbanization is often moving faster than infrastructure development.

Additionally, municipal water supplies in these cities often do not have the capacity or modern design for this level of growth. Generally, municipal budgets for tier-2 cities are tight, meaning there is little financial headroom for large-scale network overhauls.

Also, many of the existing pipes providing the water supply are old, undersized, and/or corroded, which makes them not conducive to providing the volume or reliability required by new developments.

The discord between demand and infrastructure causes a persistent water crisis. In short, population and buildings are increasing rapidly, but water infrastructure is lagging, putting pressure on cities, residents, and developers.

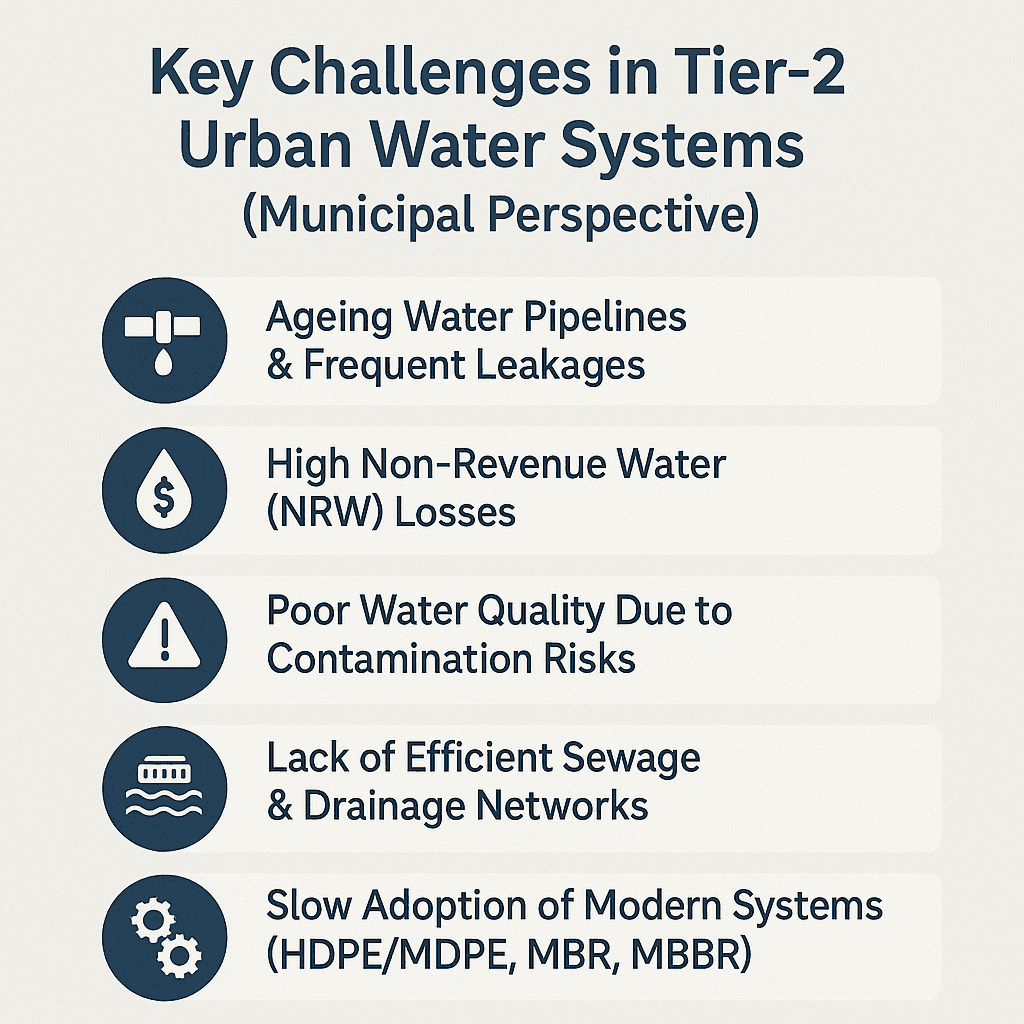

Key Challenges in Tier-2 Urban Water Systems (Municipal Perspective)

1. Ageing Water Pipelines & Frequent Leakages

Numerous municipal systems still rely on aging metal or cement pipes that corrode, crack, or fail at joints. Leakages are not only costly to fix, but waste limited water supply, and undermine long-term reliability.

2. High Non-Revenue Water (NRW) Losses

Through leakages, insufficient maintenance, and mismanagement in tracking, a large amount of water that is supplied never reaches a user. This “non-revenue water” is not only revenue lost in a city’s budget, but it also undermines conservation efforts.

3. Poor Water Quality Due to Contamination Risks

Old pipes, leaky joints, and inadequately treated inflow water can result in contamination entering the supply line. Without extreme treatment and safe delivery, risk remains high for microbial, chemical, or physical pollution.

4. Lack of Efficient Sewage & Drainage Networks

Many tier-2 cities lack adequate sewage and drainage networks. Without efficient and effective sewage treatment and reliable drainage, urban expansion will quickly outpace the ability to manage sewage and wastewater, creating risk to the environment and public health.

5. Slow Adoption of Modern Systems (HDPE/MDPE, MBR, MBBR)

While there are modern technologies available to improve reliability, like polyethylene pipelines and advanced bio-reactor treatment processes (MBR and MBBR), many municipal systems continue to operate on antiquated designs due to resistance to new materials, lack of technical capacity, or insufficient budgets to modernize.

Also Read: Compare MDPE vs HDPE pipes

Challenges Faced by Builders & Contractors in Tier-2 City Projects

1. Difficulty in Sourcing Reliable Water Supply Pipes

Contractors are nearly always faced with the challenges of sourcing piping materials that are durable and leak-free. Traditional piping solutions are often cheap, but don’t have the reliability needed for long term township infrastructure.

This is where goflo comes in, with MDPE and HDPE pipe solutions that are 100% virgin resin, food-grade polyethylene pipes that have been certified by CIPET and CFTRI for safety and durability.

2. Inconsistent Water Pressure Due to Old City Networks

When a new township is built on an existing water network, hydraulic mismatches tend to happen with old municipal lines, as the old lines cannot maintain the pressure requirements of a new development which results in low water flows or even intermittent.

goflo is able to overcome this challenge by hydraulic modeling (WaterGEMS) the pipeline diameters, zoning and pressure management so that the design can support demand.

3. Complex Installation Conditions in Congested Areas

Installing piping in crowded areas often has unique challenges such as narrow roads, extensive occupancy, limited trenching space, and multiple utility crossings. Ordinarily, rigid systems require deep excavations, which can lead to disruptions and costly overruns.

goflo’s MDPE pipes are lightweight and flexible (density 926–940 kg/m³), which makes them the ideal solution in tight installation areas. Their method of joining, known as electrofusion, enables a strong joint that remains leak-free even in the wrong conditions.

4. STP/WTP Compliance Challenges in Residential Projects

Modern residential developments are often expected to have onsite sewage treatment plants (STPs) or water treatment plants (WTPs) to produce recycled water for residential initiatives, including flushing and landscaping. It can often be frustrating to balance environmental compliance and O&M costs.

goflo provides a full-service Sewage Treatment Plant (STP) solution using a range of filtration technologies (sand, activated carbon, RO, UV) to treat wastewater and recycle it safely. goflo also provides Water Treatment Plant (WTP) solutions, including multi-grade, nano-filtration (RO, ultrafiltration), and jointing methods to reduce leaks.

The goflo Solution – Modern, Reliable, Future-Ready Water Infrastructure

goflo provides a comprehensive range of solutions directly focused on solving tier-2 water infrastructures. They do not just supply products; they design, build, and maintain entire systems.

1. Quality MDPE & HDPE Pipes for Leak-Free Water Supply

- MDPE Pipe Solution: goflo’s Medium Density Polyethylene (MDPE) pipes are manufactured using 100% virgin resin and are very flexible and able to withstand a shock or mechanical loading.

- HDPE Pipe Solution: goflo’s HDPE pipe solution is less expensive and is durable, will not support fungi, and is corrosion-resistant. They are excellent for large installations.

- Electrofusion Jointing: goflo has an electrofusion welding process to join your pipes. The joints are leak-free, long-lasting, and require less maintenance.

- Long Lifespan: There is a 50-year lifespan guarantee for the pipes that is certified internationally and in India (ISO 4427).

These processes create your maintenance-free water supply network and reduce both non-revenue water and losses due to leaking pipes.

Read More- Learn more about MDPE & HDPE pipes

2. Advanced STP/WTP Systems for Real Estate Projects

goflo provides completely integrated STP solutions for sewage treatment encompassing biological processes, pressure/multiple-stage filtration, API oil separation, odor control (biofilters and chemical scrubbers), and disinfection systems.

goflo provides a multi-barrier WTP solution for water treatment: sand filters, activated carbon, ion-exchange softeners, nano-filtration (UF, NF, RO), and UV or Ozonation. During planning, goflo also utilizes WaterGEMS hydraulic modeling to plan and size pipelines and treatment units.

The durability of components and economical design minimize operational costs, while also offering continued after-sales service.

3. End-to-End Infrastructure Services

goflo’s scope of work extends far beyond pipes or plants; they are engaged in a full-service offering for all aspects of design and construction for water infrastructure:

- Sewerage: Sewer pipes, DWC (duplex wall corrugated pipe) for sewer outfalls, and construction layouts.

- Stormwater Drainage: Engineered pipe and pipe network designs that take urban hydrology into account.

- Rainwater Harvesting: Systems to capture, store, and reuse rainwater, so the end user can become less reliant on tap water.

Pipeline Design and Installation and Commissioning: goflo is involved in the whole life cycle, from hydraulic design (with WaterGEMS) to trenching and electrofusion welding, and final commissioning.

4. Expert Technical Support for Contractors & Developers

Site Visits and Project Sizing: goflo’s engineering team visits project sites to assess site conditions, demand profiles, and pressure zones, then recommends appropriate pipe sizes and configurations.

Hydraulic Planning: With WaterGEMS, goflo maps likely zones, models demand patterns (peak/off-peak), and simulates possible future extensions.

Training and Installation Assistance: Engineers assist contractors by providing on-site guidance on electrofusion welding, test plans, and hydrostatic pressure testing to ensure that the system can be safely handed over without leaks.

After Sales and Maintenance: goflo provides ongoing maintenance support that includes not just monitoring, but also annual inspections as required.

Case Example: How Smart Piping Improved a Tier-2 Township’s Water Supply

While goflo’s website does not name specific clients’ townships, one can envision a basic before-and-after situation based on their service offerings:

- Before: A new residential township in a Tier 2 city has low water pressure, high maintenance costs, and recurring leaks. The municipal supply system is past its useful life, and corrosion or leaks occur in the distribution lines. Non-revenue water is high as residents voice concern about water quality and interruptions in service.

- After goflo Deployment: goflo’s team undertakes a site survey and hydraulic modeling, followed by the design of a zoned MDPE/HDPE pipeline network. The pipes are installed with electrofusion joints and tested for leaks. In addition, goflo constructs a water treatment plant and STP that allows for recycling sewage in the flushing process and for landscaping.

Benefits of Choosing goflo for Tier-2 City Water Projects

Here are the major benefits associated with using goflo to construct water works in a tier-2 city:

1. Long-Term Durability with Zero Corrosion

Polyethylene (PE) pipes are resistant to corrosion, fungi, and degradation, all of which means goflo systems are designed for indefinite service; goflo warrants this for 50 years.

2. Faster Installation & Lower Maintenance

Flexible MDPE and HDPE pipes are lighter-weight and easier to work with. Electrofusion joints eliminate most of the leak threat. This means fewer rework jobs or service calls for the life of the goflo system, which reduces project and operating costs.

3. Safe, Hygienic Drinking Water Distribution

goflo uses a food-grade, virgin resin for their pipe that has been certified by CFTRI and CIPET to be a hygienic way to distribute drinking water. The ultra-low leak risk with goflo stacks together to better protect the purity of the water.

Also Read: Are MDPE pipes safe for potable water?

4. Reduced Lifetime Cost of Ownership

Upfront material cost appears higher than legacy products, but the overall savings over time will stack up as the functions of fewer leaks (reduced NRW), lower maintenance, and longer-lasting pipeline systems result in effective savings. goflo uses software (WaterGEMS) to ensure the system has been designed properly, which reduces over-specification and material wastage.

Lastly, goflo will provide after-sales service and perform annual inspections to ensure the systems continue to operate efficiently.

FAQ’s

Q. What makes goflo’s pipes appropriate for tier-2 city projects?

Q. How does goflo improve water pressure in new townships?

Ans: goflo uses WaterGEMS hydraulic modeling and tackles proper pipe sizing, zoning, and pressure management to achieve consistent and reliable flow.

Q. What treatment systems does goflo provide for residential projects?

Ans: goflo provides complete STP and WTP solutions using biological treatment, filtration, disinfection, and advanced membrane technologies to ensure safe and reusable water.

Q. Why is goflo cost-effective through a project’s lifecycle?

Ans: Reduced leaks and maintenance, the length of use, optimized design, and continued after-sales support all work to significantly reduce the overall operational and replacement costs throughout the lifecycle of the project.

Final Thoughts – Building Stronger, Safer Tier-2 Cities with goflo

Tier-2 cities constitute an important battleground for the water infrastructure future of India. These growing urban centers are pressed by rising populations, shrinking budgets, and aging systems, creating a perfect storm for water loss, quality, and inefficient networks.

Using modern materials (MDPE, HDPE), integrating smart hydraulic designs (WaterGEMS), and employing modern treatment methods (WTP, STP, MBBR/MBR), goflo offers a complete, future-proofed infrastructure solution.

For developers, municipalities, and contractors in Tier 2 cities, collaboration with goflo is not simply pipes or plants; it is an enduring, long-term ecosystem. goflo allows cities to develop water systems that support demand, preserve valuable resources, and reduce life-cycle costs, thus enabling cities to build a strong, safe, and sustainable urban growth.